Infrastructure

Promac’s world class manufacturing facility is equipped with dedicated Heavy Fabrication / Machining capabilities and Quality Assurance department

Machine Shop

- Vertical Turret Lathes with machining capacity up to 10.5 mtr Φ and can take weight upto 100 tons work piece & up to 3.0 mtr height.

- Gear Hobbing machines up to 7 mtr dia, 40 module and 1 mtr face width.

- Floor Boring Machines up to 6m travel length with spindle dia of 130 mm.

- Latest CNC with horizontal & vertical turning machines and other heavy-duty lathes.

- Automated Submerged Arc Welding machines

Fabrication

- Plate Rolling Machines for cold rolling thickness up to 110 mm thick x 3 m width

- Robo Plasma Cutting Machine – 4 Axis

- CNC Plasma Arc / Oxy Fuel Cutting

- Shot Blasting Booth – 18m x 7m x 5m (LxWxH)

- Heat Treatment Furnace – 5m x 6m x 5m (LxWxH)

Laboratory & Quality Control

- Spectro Analyser – Chemical Analysis of 27 Elements

- Universal Testing Machine (UTM) – For Tensile Strength and Elongation

- Magnetic Particle Testing

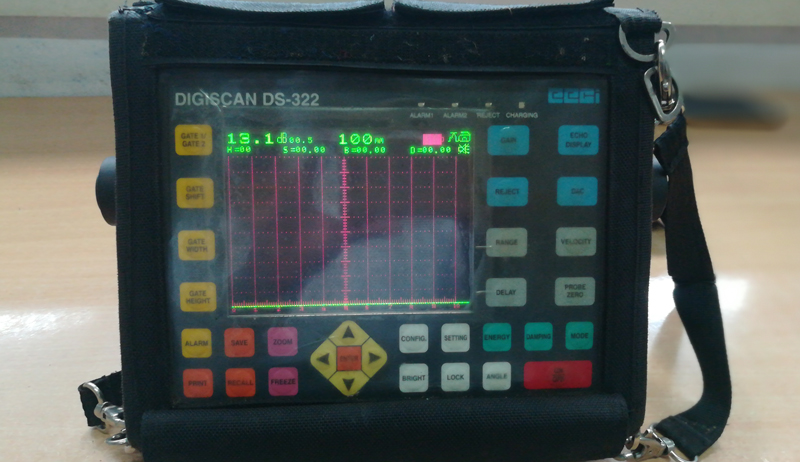

- Non-Destructive Ultrasonic Testing Machine – Ultrasonic Testing of Materials

Copyright 2021 © Promac Engineering Industries Limited. All rights reserved